5-AXIS MACHINING TOOLS

Achieving creativity beyond imagination. Dijet has responded to difficult issues through its in-house integrated production, from material design to final products, and has combined its many years of know-how into the “Vertical and Horizontal Mugen Series.” The combination of a uniquely shaped tool and a 5-axis machining machine reduces setup time and achieves high efficiency and high quality machining.

Product list of 5-axis machining tools

mirror barrel

Adopts a barrel-shaped cutting edge to dramatically reduce finishing machining time on a 5-axis machine. Adopting a barrel shape with a large radius on the side or bottom, it significantly reduces machining time, especially when machining with a 5-axis machine.

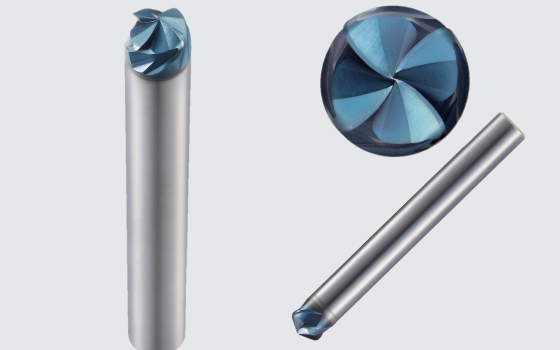

tulip S head

A solid modular head with a high-precision taper barrel shape with a large R1500 cutting edge and a form accuracy of ±0.01mm or less. The large radius on the outer periphery makes it possible to increase the machining pitch when machining sloped surfaces, enabling high-precision machining, and the radius at the tip makes it ideal for corner R machining.

fuji barrel

A solid barrel tool that allows high efficiency machining of sloped surfaces and bottom surfaces with a large R cutting edge on the front taper section. The large radius of the front taper allows for a larger machining pitch when machining sloped surfaces, enabling high-precision machining.

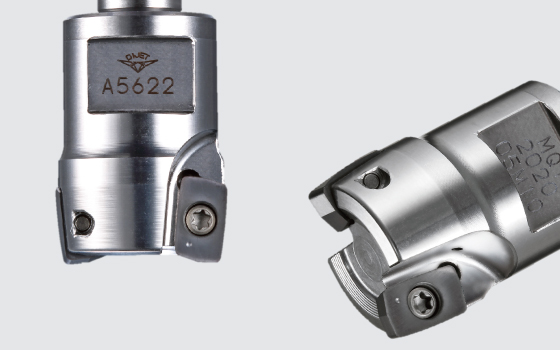

High precision version QM Max

High-precision main body design realizes even higher precision machining. This is a high-precision version that further improves the accuracy of the QM Max MQX type. Ideal for finishing machining, and provides good surface roughness when used in combination with H class inserts.