Wear resistant tools

Dijet’s wear-resistant tools leverage our strengths in integrated production from raw materials, select the optimal material for each application, and provide our customers with unique technology and creativity backed by a wealth of experience cultivated over many years. Contribute to manufacturing.

About Dijet wear-resistant tools

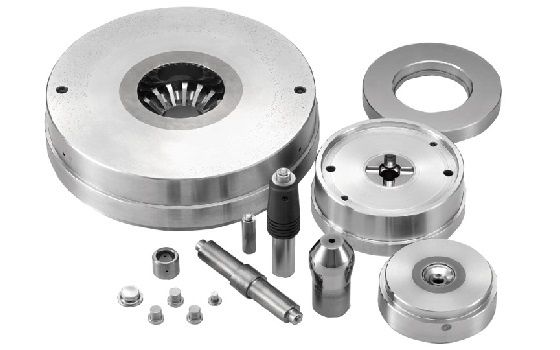

Plastic processing tools

Demand for plastic working is increasing from the perspective of shortening product processing lead times and creating net shapes. Super hardening of plastic working tools through proper grade selection and tool design greatly contributes to extending tool life and improving product quality.

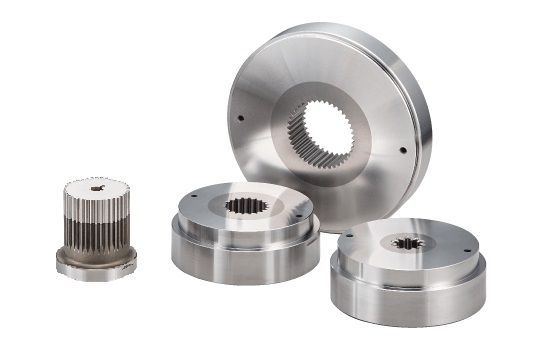

Various mechanical parts

Super hardening is progressing in various mechanical parts in various industrial fields. Its long life due to its excellent wear resistance and impact resistance also has the effect of reducing the frequency of tool replacement and regrinding, which can improve productivity.

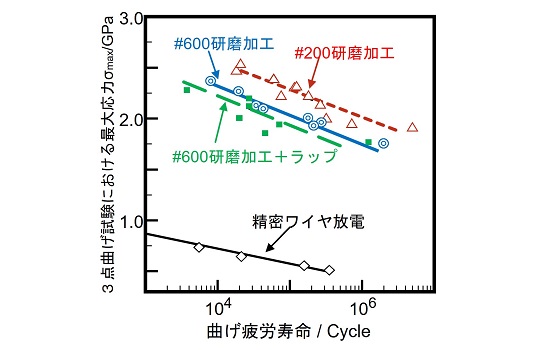

Efforts to improve the life of carbide tools

We are conducting research on the fatigue and wear characteristics of cemented carbide, which are factors in tool life, and by understanding these characteristics, we are working on technological development with the aim of further improving the life of cemented carbide tools.

Click here for Dijet grade characteristic values

Examples of products we handle

Cold forging mold

Powder molding mold

Press mold

Other special tools

Technology introduction of wear-resistant tools

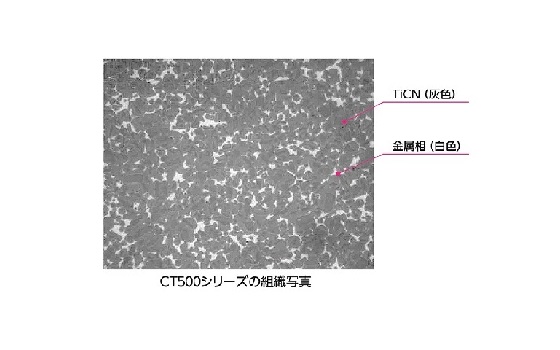

Thermetal

A new environmentally friendly tool material that is made of titanium carbonitride (TiCN) as an alternative to WC-Co cemented carbide.

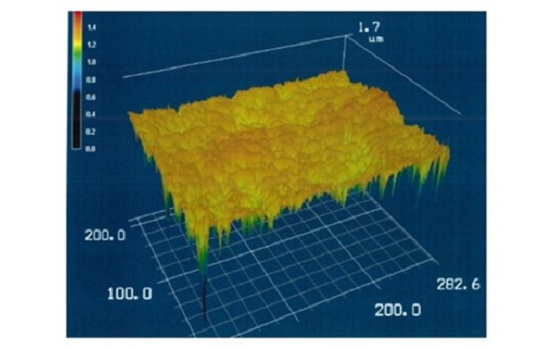

Dimple processing

Micropools generated on the mold surface retain lubricant, reducing machining load and improving seizure resistance.

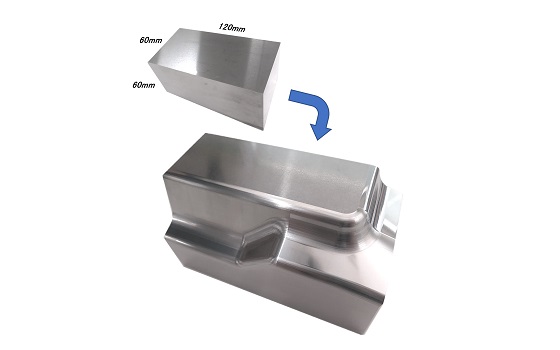

Direct carving of carbide

It suppresses surface deterioration and shape non-uniformity, which were concerns in electrical discharge machining, and stably reproduces various free-form surface shapes.

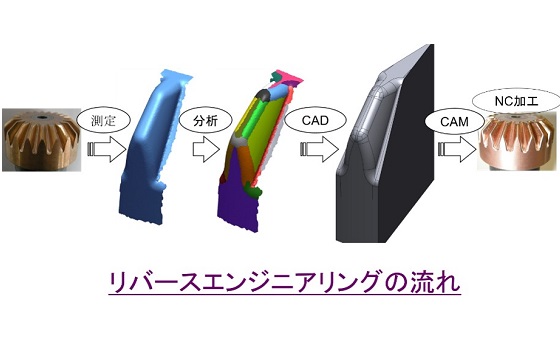

Reverse engineering

A digital technology that creates a 3D-CAD model based on shape data obtained by measuring an existing item and reflects it in the design.